Welding

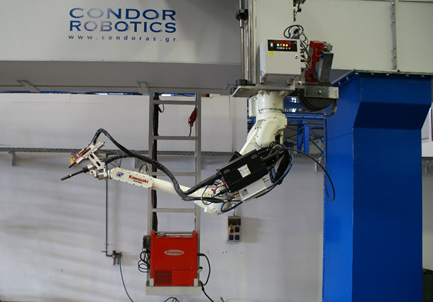

One of the main applications of robotics is Robot welding. There are many advantages of using a robotic arm in welding. High precision welding, repeatability, flexibility, production automation, quality in special welds, increased productivity, safety, economy. All this means producing high quality products that can stand upright in the competitive world map environment.

The welding machines we use in our applications are designed to work in conjunction with Robot (selecting and changing welding parameters through the Robot Controller, diagnostic functions via Robot, and placing the wire transducer on the Robot. They are water cooled, pulse and power up to 500 A.

The welding pin is water-cooled, with detachable cables for easy maintenance.